Well some of you may remember my first ever Blog. I related to my work on a Ian Lindsay Model's CLX/NLCX Kit. I had placed a On Track Models Chassis from one of their LLV RTR Models under the ILM's CLX Kit. I never really finished that model but it is now painted waiting weathering. It looked good at the time as there was no real better options to Model a NCLX.

Over time Auscision announced that they were working on their JLX/NLJX product so I shelved the ILM's Kit waiting to see what they would come up with. It was pretty dam good so my thought process started on converting one of these into a NLCX. So what I can say, it was a success. The Auscision model addressed many short comings of the ILM body sides. The most obvious being the off centre doors. It also introduced rivet detail in the body which is simply achieved with injection moulding. Anyway here is the end results-

Very Happy with it

Here is a photo essay of how-

It started out as the Auscision NLJX

It was sacrificed and a OTM's LLV. The LLV body may live on as a farm shed? The chassis from the NLJX will live on as a NCRX when I get around to it. So for two items of rollingstock I will be getting two back in other forms and a farm shed.

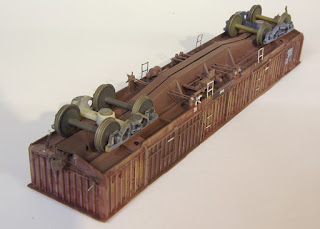

The Chassis and Floor were both used from the LLV

A credit to the manufacturers of these, When the JLX was cut down, the LLV floor fit under perfectly with not gaps what so ever.

Working out the height

Next to the ILM version

ILM on top. This shows the issue with the doors being off centre

The Prototype

I petty much left the under floor as OTM. My aim was to make the model look pretty much how it would look straight out a OTM's or Auscision Box minus the weathering

I could not ignore some missing detail around the underfloor so this was added using styrene strip.

I find one of the easiest methods for adding styrene is to spot it with super glue and handle as a long piece. I then cut it down to size with a sharp razer blade after the glue has set. I would do three at a time cut to different lengths as to give room to work and when stuck, cut to size. The off cuts were then reused for the next three till they were too short to work with.

Cutting these supports to the right shape

The lifting supports need a few different shapes to get it right.

Other than the styrene work, the only other parts added that are not from the original models was the Brass Air Hoses and the brake rigging support just next to the brake wheel. That was from AR Kits brake parts. The Bogies are from AR Kits with Auscision P88 Wheels fitted. The coupler is a Kadee 58. The uncoupler bar is from the LLV. I used a Kadee red washer to adjust the height and give the wheels a little more clearance from the underfloor. I also hollowed out the cut off's on the 2CG Bogies as an added detail. SEM brake shoes have been added to the bogies.

AR Kits LLV brake support cut down. The Ladders are from the NLJX

With the ILM

Primed with Model Master Primer

Weathering base coat applied using Tamiya Enamels

Sitting next to a weathered NLJX

After applying some washes using the Tamiya Enamels in washes of turps. Only after the model was left sit for a couple of weeks to set the original weathering coat.

Some Prototype shots from Norm Bray's Flickr site used with permission

I based my weathering on 10074 but numbered it 5209 to make decaling easier.

I hate decaling

Anyway that is pretty much it

Cheers Justin Moy